Low Carbon Material Requirements Development

Project Background

The General Services Administration (GSA) established the country’s first federal Buy Clean requirements for the procurement of lower embodied carbon construction materials. These requirements apply to four key construction materials, concrete, asphalt, steel, and glass![]() , that represent a significant segment of federal construction, and will catalyze the production of construction materials with substantially lower levels of embodied carbon.

, that represent a significant segment of federal construction, and will catalyze the production of construction materials with substantially lower levels of embodied carbon.

Since at least 2020, GSA, the Department of Transportation (DoT) and the Environmental Protection Agency (EPA) have been engaged in efforts to foster the use of low-carbon materials in federal construction projects. In 2020, GSA’s Green Building Advisory Committee![]() (GBAC) convened an Embodied Energy Task Group

(GBAC) convened an Embodied Energy Task Group![]() composed of design and construction experts from private, nonprofit, and government (including EPA) sectors to develop recommendations on incorporating low-carbon standards into federal construction and in 2021 developed initial low-carbon standards for concrete and asphalt as part of the Bipartisan Infrastructure Law’s (BIL) paving program for GSA land ports of entry. As a result of these initial low-carbon efforts, GSA, EPA, and DoT were able to “hit the ground running” when Congress and the President enacted the Inflation Reduction Act (IRA) in August 2022.

composed of design and construction experts from private, nonprofit, and government (including EPA) sectors to develop recommendations on incorporating low-carbon standards into federal construction and in 2021 developed initial low-carbon standards for concrete and asphalt as part of the Bipartisan Infrastructure Law’s (BIL) paving program for GSA land ports of entry. As a result of these initial low-carbon efforts, GSA, EPA, and DoT were able to “hit the ground running” when Congress and the President enacted the Inflation Reduction Act (IRA) in August 2022.

Sustainability Strategies

The knowledge gained from the development of the initial low-carbon standards was used to issue new standards for low carbon concrete and environmentally preferable asphalt, which were applied![]() starting in March 2022 at projects along the nation’s borders. These new standards were also integrated into the scopes of work for other projects, as well as GSA’s P100 facilities standards

starting in March 2022 at projects along the nation’s borders. These new standards were also integrated into the scopes of work for other projects, as well as GSA’s P100 facilities standards![]() .

.

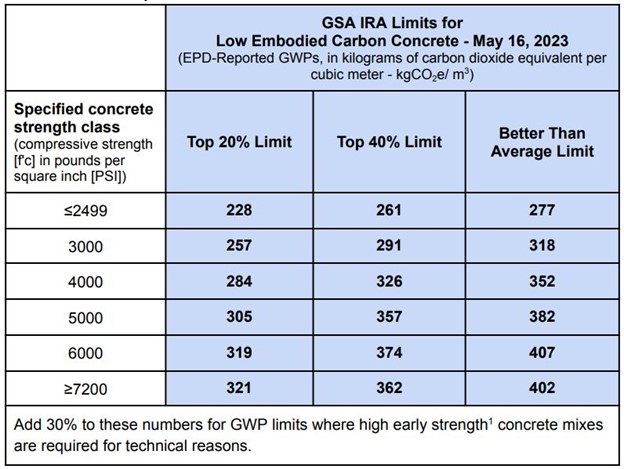

The interim Buy Clean low embodied carbon (LEC) requirements![]() were issued in May 2023 in support of an eleven-project pilot

were issued in May 2023 in support of an eleven-project pilot![]() expanded to include two new material categories (steel and glass), while substantially strengthening requirements for concrete and asphalt. These first-of-their-kind project requirements set an example for how federal agencies can determine the industry average global warming potential (GWP) of materials and products. They also implement a “waterfall” approach of seeking the best performing (top 20%, lowest-carbon) materials where available first, with the top 40% being the next tier, and better than average the final tier. This leverages data from publicly-available environmental product declarations (EPDs).

expanded to include two new material categories (steel and glass), while substantially strengthening requirements for concrete and asphalt. These first-of-their-kind project requirements set an example for how federal agencies can determine the industry average global warming potential (GWP) of materials and products. They also implement a “waterfall” approach of seeking the best performing (top 20%, lowest-carbon) materials where available first, with the top 40% being the next tier, and better than average the final tier. This leverages data from publicly-available environmental product declarations (EPDs).

This group has provided its contractors and manufacturers with targets to reduce the carbon footprint of high embodied carbon materials. This public-private collaboration will boost the competitiveness of American manufacturers, while reducing the embodied carbon of materials used in GSA’s Public Buildings Service (PBS) buildings.

GSA was the first agency to implement national Buy Clean policies, and the first to implement IRA low-carbon appropriations. The development of Low Embodied Carbon Material Requirements has already started reducing GSA’s carbon emissions from construction materials. It has galvanized the Federal government’s Buy Clean![]() efforts and provided a blueprint for Federal agencies to rapidly implement a Buy Clean policy that complies with IRA’s low embodied carbon provisions. GSA’s action boosts U.S. manufacturing by requiring materials that generate substantially lower greenhouse gas emissions from extraction, transportation, and manufacturing -- such as locally-sourced, American-made materials.

efforts and provided a blueprint for Federal agencies to rapidly implement a Buy Clean policy that complies with IRA’s low embodied carbon provisions. GSA’s action boosts U.S. manufacturing by requiring materials that generate substantially lower greenhouse gas emissions from extraction, transportation, and manufacturing -- such as locally-sourced, American-made materials.

Over a half-dozen GSA projects have already met GSA’s Buy Clean standards to date. Now GSA has started applying more aggressive requirements to all its IRA-funded purchases of concrete, asphalt, steel, and glass. GSA’s planned IRA projects alone are expected to have a substantial beneficial impact: they are estimated to reduce the agency’s carbon emissions from construction materials by about 26,000 metric tons, equivalent to taking more than 5,000 gasoline-powered vehicles off the road.