Embodied Carbon

Embodied carbon, from building materials and construction, comprises about a third![]() of the built environment's substantial total carbon footprint, and that share is expected to grow as buildings trend toward higher operational efficiency. Given that at least 8% of global GHG emissions

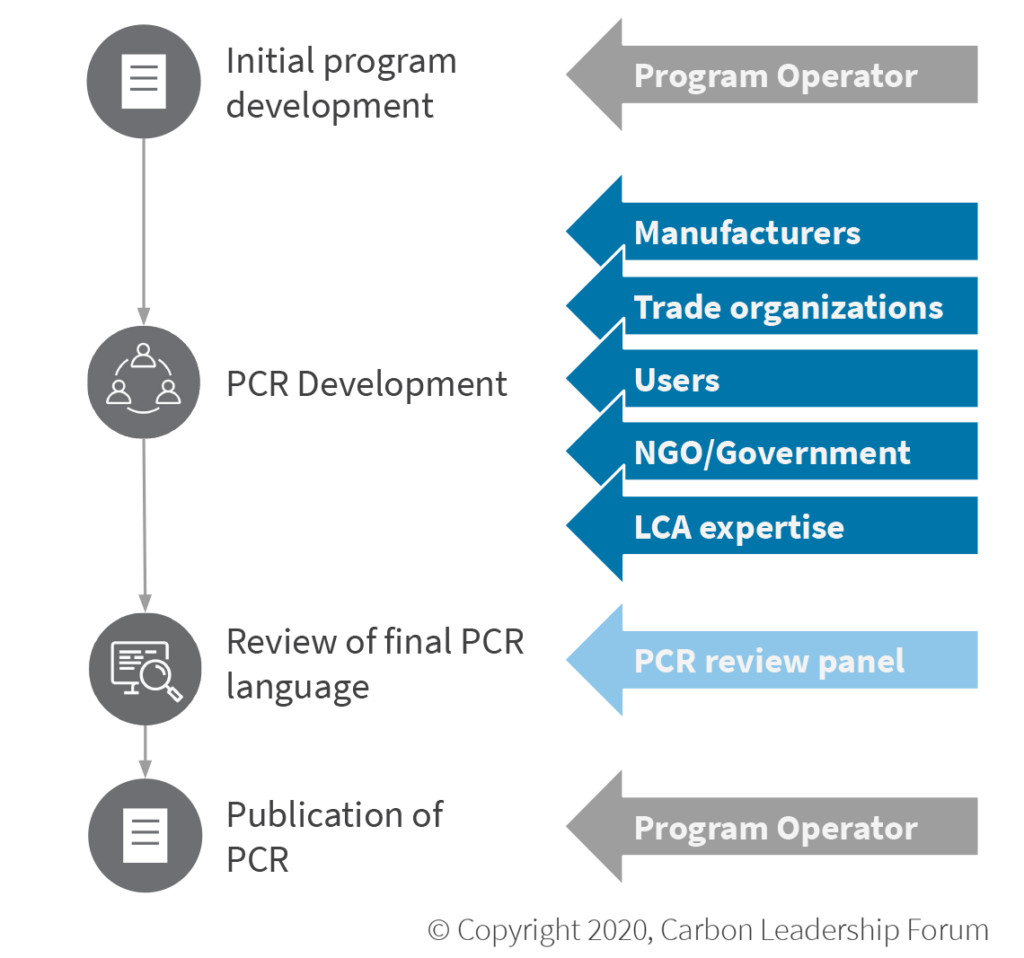

of the built environment's substantial total carbon footprint, and that share is expected to grow as buildings trend toward higher operational efficiency. Given that at least 8% of global GHG emissions![]() may currently be attributed to manufacturing building construction materials, reducing embodied carbon is an important climate mitigation strategy. While operational carbon can be reduced over time as a result of implementing strategies such as energy efficiency upgrades and the use of renewable energy sources, embodied carbon is locked in as soon as the building is built. Whether new construction or renovation, it’s critical to address and plan to reduce embodied carbon early during the planning and design phases of a project. Quantifying embodied carbon requires understanding a few key concepts: Global Warming Potential, Whole Building Life Cycle Assessment, Environmental Product Declarations, and Product Category Rules.

may currently be attributed to manufacturing building construction materials, reducing embodied carbon is an important climate mitigation strategy. While operational carbon can be reduced over time as a result of implementing strategies such as energy efficiency upgrades and the use of renewable energy sources, embodied carbon is locked in as soon as the building is built. Whether new construction or renovation, it’s critical to address and plan to reduce embodied carbon early during the planning and design phases of a project. Quantifying embodied carbon requires understanding a few key concepts: Global Warming Potential, Whole Building Life Cycle Assessment, Environmental Product Declarations, and Product Category Rules.

Embodied Carbon Basics and Definitions

Embodied Carbon Components

- Whole Building

- Interior

Whole Building Life Cycle Assessment (WBLCA)

Before implementing embodied carbon reduction strategies, it’s imperative to estimate the building’s/project carbon footprint and there are three approaches for doing that, depending on the availability of data, level of effort, and needed details. The first is a complete WBLCA, including building materials, construction and end of life activities. A WBLCA is the most accurate method to estimate embodied carbon and GWP in buildings. When done early in the design phases, a WBLCA can lead to the greatest reductions in embodied carbon. For example, a WBLCA may provide insights that lead the project team to consider several design options for different structural systems, so that the design with the lowest embodied carbon can be specified.

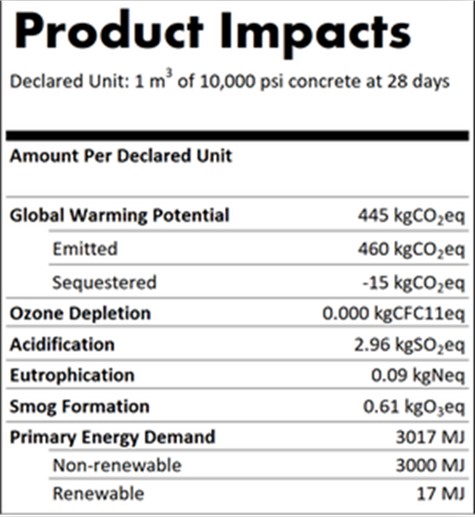

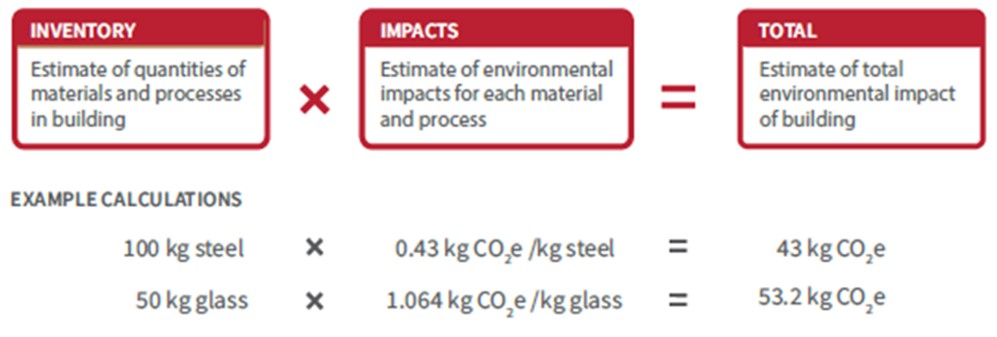

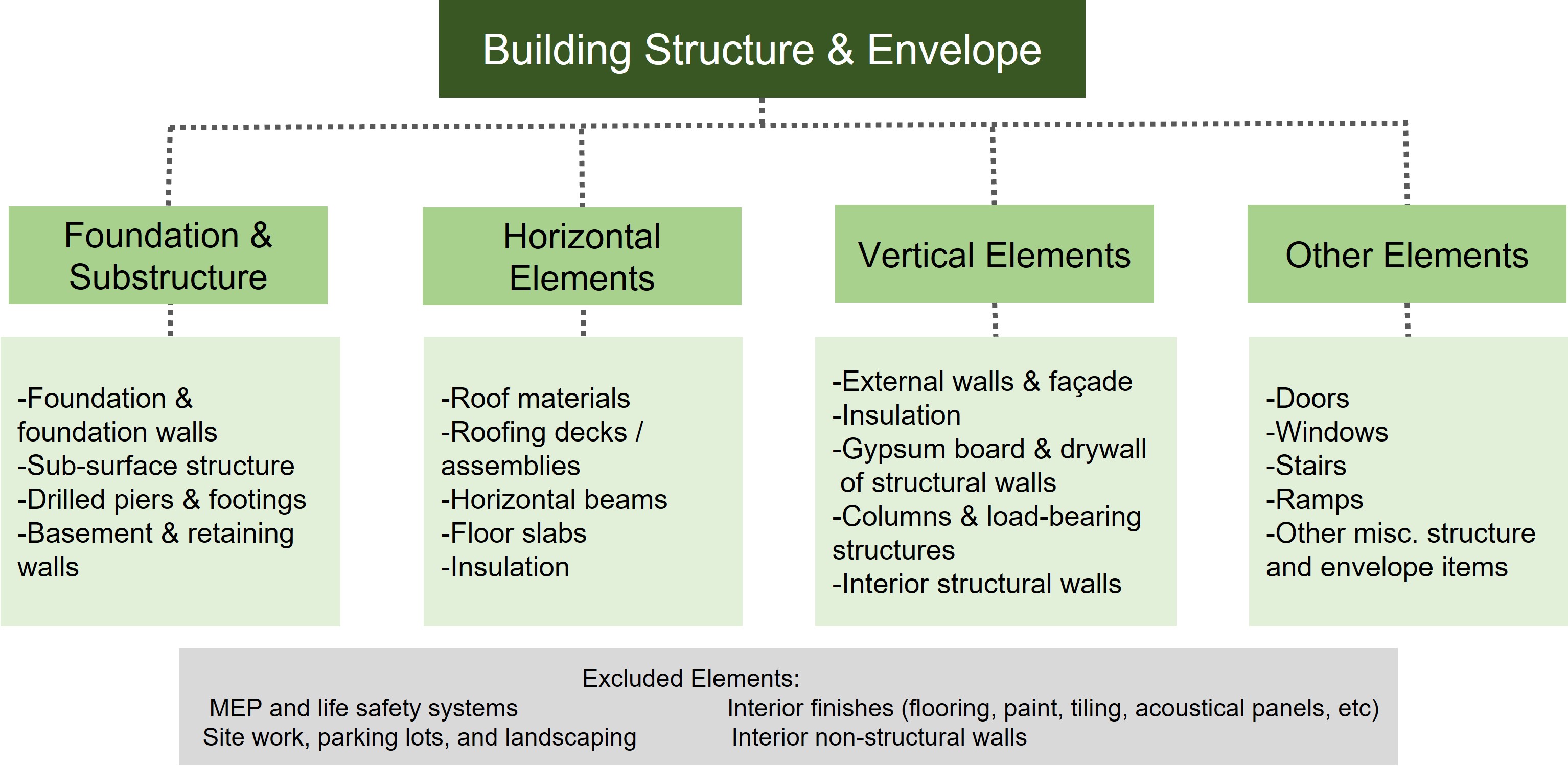

A second method to estimate embodied carbon, if a WBLCA is not feasible, is to collect EPDs and track the quantities, manufacturer, specifications, and other product aspects using the simple calculation in Figure 1 and focusing on the essential building elements listed in Figure 2. Typically, structural materials like concrete and steel make up the majority of a building’s embodied carbon. Utilize EPDs to validate reductions estimated during design by requiring the collection of supply chain specific EPDs during procurement.

Credit: Cannon Design

A third approach, if a WBLCA and collecting EPDs are not feasible, is to use industry averages to estimate the embodied carbon of a building. The Carbon Leadership Forum’s Embodied Carbon Benchmark Study![]() analyzed over 1,000 building LCAs and concluded that the initial embodied carbon from Stage A in a typical new construction building is less than 1,000 kg CO2e per square meter (from the structure, foundation, and enclosure). 1,000 kg CO2e per square meter can serve as a baseline for new construction projects looking to reduce embodied carbon. The Carbon Leadership Forum’s WBLCA Benchmark Study v2 will expand upon this research to determine geographically and typologically specific benchmarks for buildings, systems, and assemblies modeled with consistent scope and background data.

analyzed over 1,000 building LCAs and concluded that the initial embodied carbon from Stage A in a typical new construction building is less than 1,000 kg CO2e per square meter (from the structure, foundation, and enclosure). 1,000 kg CO2e per square meter can serve as a baseline for new construction projects looking to reduce embodied carbon. The Carbon Leadership Forum’s WBLCA Benchmark Study v2 will expand upon this research to determine geographically and typologically specific benchmarks for buildings, systems, and assemblies modeled with consistent scope and background data.

Embodied Carbon Reduction Strategies

While fossil fuel combustion at different life cycle stages constitutes the primary source of GHG emissions for most organizations, GHG mitigation involves a broad range of strategies that go well beyond energy and procurement.

- Adaptive reuse of existing buildings, instead of constructing new ones

- Carbon injection and/or using low-carbon concrete mixes

- Carefully considering carbon-intensive materials such as concrete, steel, and aluminum

- Selecting carbon-sequestering, bio-based materials (carbon storage)

- Reusing materials

- Using high-recycled content materials

- Minimizing waste

- Choosing materials with longer life spans

- Landscaping

GSA’s embodied carbon policies for Inflation Reduction Act projects![]() leverage a combination of GWP limits and EPD requirements for certain Buy Clean construction material categories, starting with concrete, asphalt, steel, and glass.

leverage a combination of GWP limits and EPD requirements for certain Buy Clean construction material categories, starting with concrete, asphalt, steel, and glass.

Procurement of Low Embodied Carbon Materials and Products

Thoughtful planning and design that prioritizes material efficiency and reuse minimizes the quantity of materials and products that will need to be procured and installed. Once those planning and design decisions are made, it is time to procure the best materials and products to meet the defined need.

Why does low embodied carbon procurement matter?

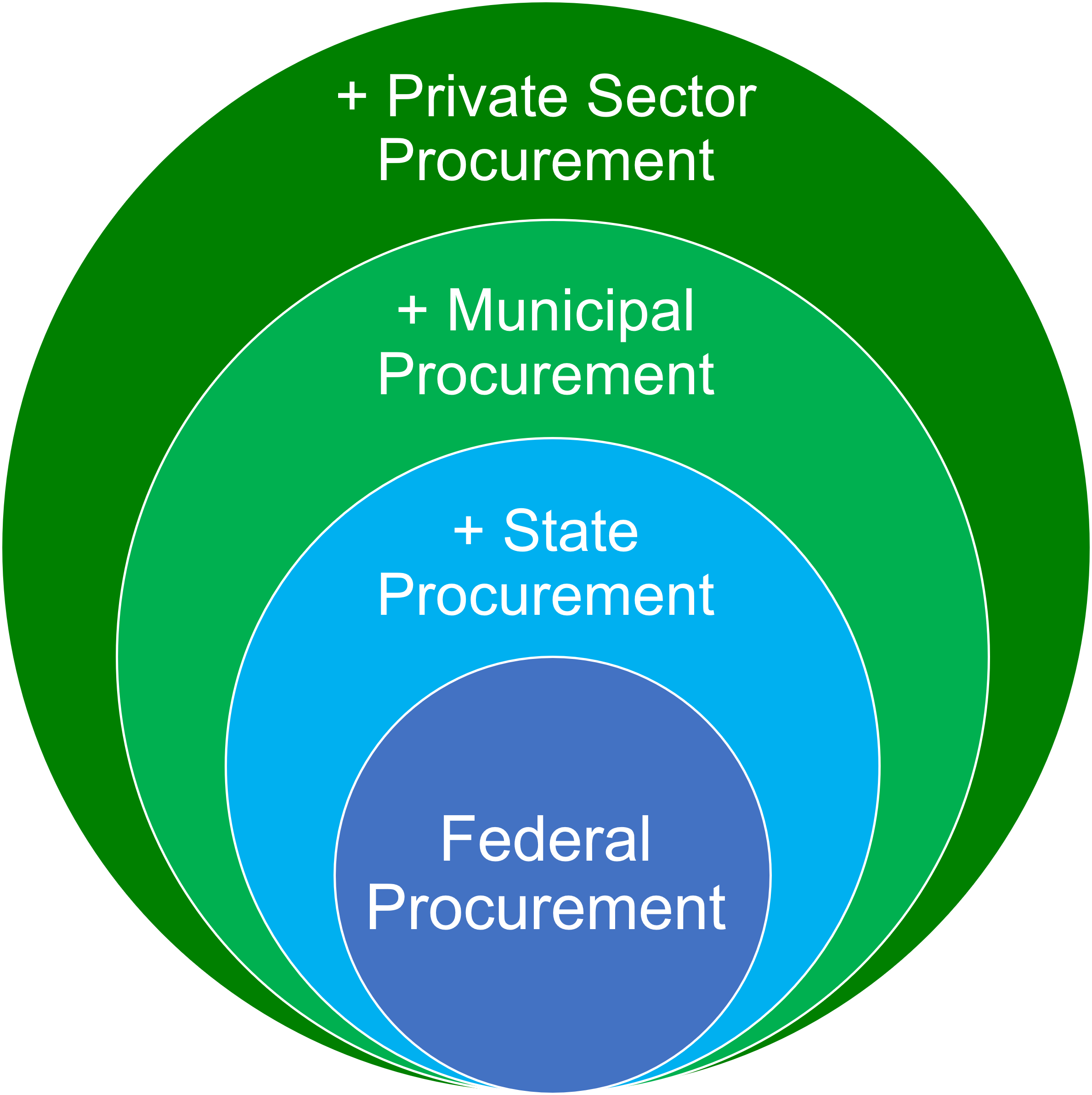

Approximately 32% of construction-related embodied carbon in the United States is from public (government-funded) projects, and 46% of Portland cement produced in the United States is used on public projects.1

Low carbon materials are a fast-growing area of interest. Historically, the embodied carbon of materials has not been properly considered, requested, or valued. That has hindered broad market penetration. Encouraging the growth of clean domestic manufacturing can protect existing local manufacturing jobs and support new careers related to technology development and maintenance, environmental analysis, and skilled deconstruction of buildings for reuse. Low carbon materials can also be found at competitive prices. According to the Rocky Mountain Institute![]() , embodied carbon in some buildings can be reduced by 19% to 46% with less than a 1% increase in project cost.

, embodied carbon in some buildings can be reduced by 19% to 46% with less than a 1% increase in project cost.

Now is the time to rethink the way we source materials and build federal buildings to support decarbonization.

Which materials have the biggest impact?

- By volume

Widely used construction materials, like concrete and steel, are responsible for significant GHG emissions. This is due to both the energy intensity required for their production and to their extensive use in constructing much of our infrastructure and built environment. For example, concrete is the most widely used construction material in the world, and is responsible for 6-10% of GHG emissions. - By impact

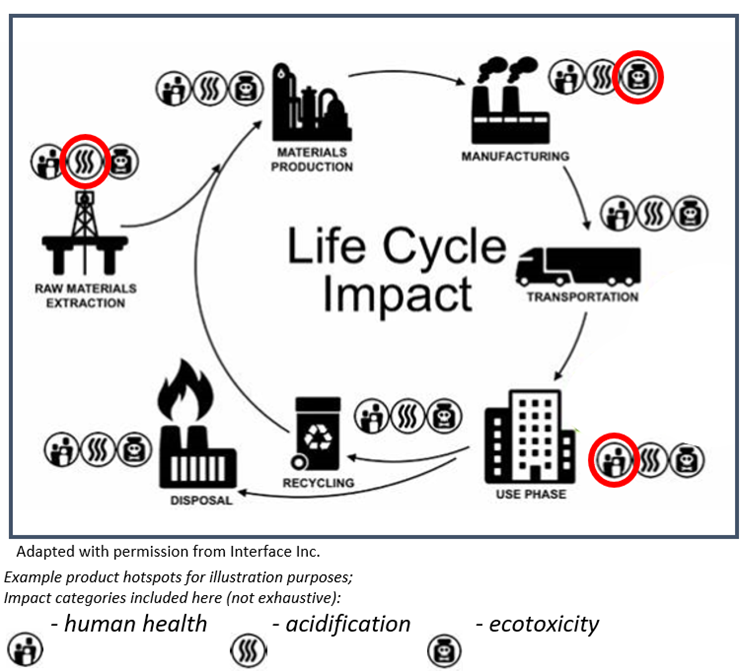

Materials like steel, concrete, asphalt, glass, aluminum, and PVC pipe contain a high quantity of embodied carbon due to the energy-intensive processes used to extract raw materials, like limestone, taconite ore, petroleum, and silica, and to then convert those raw materials via industrial processes into an end product. For example, roughly 40% of concrete's GHG emissions are from the burning of fossil fuels in the manufacturing process, and the remaining 60% are from naturally occurring chemical reactions during processing. The U.S. manufacturing sector is responsible for nearly a third of U.S. GHG emissions, with the production of steel, concrete, asphalt, and flat glass accounting for nearly half of all U.S. manufacturing GHG emissions.2 - By Hotspot

Hotspots are points in a supply chain or a product’s life cycle with the most significant environmental impacts, as determined by a LCA. These vary significantly by sector and PCR (for example, concrete EPDs do not include the embodied carbon associated with procuring sand from other parts of the world). Impacts include GWP as well as human health, acidification, ecotoxicity, and eutrophication. Hotspot analysis can identify:- Impactful life cycle stages

- Significant impacts (e.g., toxic chemicals)

- Affected environment of concern (e.g., impact to water)

- Issues (e.g., run-off from processes)

- Priorities for prevention or mitigation

Materials

This list reflects some of the more commonly-purchased materials for typical construction and renovation projects.

- Concrete

- Steel

- Asphalt

- Glass

- Aluminum

- Insulation

- Roofing

- Wallboard/gypsum board/drywall

- Structural engineered wood, including structural fiberboard

Materials such as concrete, asphalt, steel, glass and aluminum are component parts or ingredients used in construction projects. They do not come pre-packaged or with individual identification numbers. These materials also tend to vary regionally based on the energy sources that power the plants in which they are made and the raw materials used in their manufacture. Use this interactive map![]() 3 showing the location of manufacturing plants that produce asphalt, cement, concrete, glazing or steel and provide EPDs to the EC3 tool. American-made lower-carbon construction materials take priority in federal procurement and federally-funded projects. Local and regional sourcing can reduce transportation emissions.

3 showing the location of manufacturing plants that produce asphalt, cement, concrete, glazing or steel and provide EPDs to the EC3 tool. American-made lower-carbon construction materials take priority in federal procurement and federally-funded projects. Local and regional sourcing can reduce transportation emissions.

In May 2023, GSA launched a pilot of new requirements![]() for the procurement of substantially lower embodied carbon construction materials in GSA projects funded by the Inflation Reduction Act (IRA). The pilot, applying the GSA interim IRA Low Embodied Carbon Material Requirements

for the procurement of substantially lower embodied carbon construction materials in GSA projects funded by the Inflation Reduction Act (IRA). The pilot, applying the GSA interim IRA Low Embodied Carbon Material Requirements![]() into procurement for eleven GSA construction and modernization projects, will generate insights into regional market availability of qualifying products and materials, and inform adjustments that may be needed for GSA’s final set of material requirements for its IRA-funded projects. The Federal Highway Administration (FHWA) developed this resource

into procurement for eleven GSA construction and modernization projects, will generate insights into regional market availability of qualifying products and materials, and inform adjustments that may be needed for GSA’s final set of material requirements for its IRA-funded projects. The Federal Highway Administration (FHWA) developed this resource![]() related to the construction materials eligible for FHWA’s Low Carbon Transportation Materials Grants (LCTM) Program

related to the construction materials eligible for FHWA’s Low Carbon Transportation Materials Grants (LCTM) Program![]() and other applicable Federal-aid programs funds.

and other applicable Federal-aid programs funds.

Strategies

- Require comparative WBLCA at the design phase to drive material selections and design strategies that can help minimize embodied carbon.

- Utilize more bio-based materials, like wood products, that are low in embodied carbon and high in stored carbon.

- Require supply chain-specific EPDs (see interactive map

3 of plants with EPDs in EC3).

3 of plants with EPDs in EC3). - Contract with firms whose materials perform better than maximum GWP limits established using industry-average and/or product-specific data.

Products

Products may be low carbon, but relatively few have EPDs to date. As EPDs become more prevalent, it will become easier to identify products with lower GWP, such as in these product categories:

| Product Category Rules (Green Procurement Compilation) | Products with EPDs (SFTool Product Search) |

|---|---|

| Building Insulation | Building Insulation |

| Wallboard/Gypsum Board/Drywall | Wallboard/Gypsum Board/Drywall |

| Acoustical Ceiling Tile | Acoustical Ceiling Tile |

| Paint | Paints and Coatings |

| Furniture | Furniture |

| Flooring: Carpet | Carpet |

| Flooring: Hard Surface | Floor Coverings (Non-Carpet) |

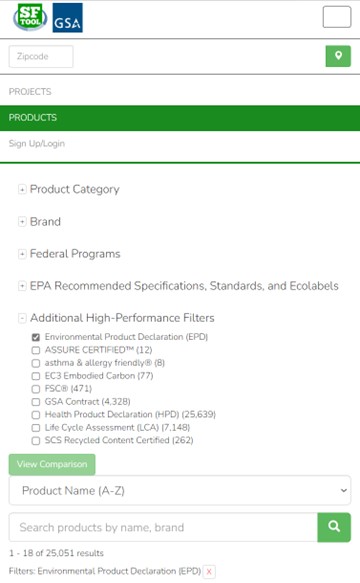

Search for items in these categories in the SFTool Procure section and on SFTool Product Search![]() .

.

Remember: Just because a product has an EPD doesn’t mean it is a high-performance product. Also note that low embodied carbon materials does not imply that they meet the statutory requirements for use of low-embodied carbon materials in the Inflation Reduction Act, Section 60116.

Procurement Approaches

Common practice is to meet minimum specifications and then select materials or products based on price. Where sufficient EPDs are available, consider a shift to meeting the minimum specifications and then weigh proposals based on innovation and embodied carbon.

Another viable approach is to require that the embodied carbon of applicable materials falls below a maximum level as shown by an EPD. Products that outperform that baseline may be given extra weight in cost of performance selection criteria.

Leveraging its national role and purchasing power, GSA has launched a material approach requiring EPDs for select key materials, and applies a whole-building embodied carbon reduction measure to all its new construction and major modernization design starts.

Procurement Strategies Supporting Decarbonization

Review projects with practical recommendations:

- Total carbon is a priority metric: Make it clear to the marketplace that total carbon, which includes both embodied carbon and operational carbon, is a priority metric.

- It is important to not value embodied carbon over operational carbon where operational efficiency is more important, e.g. chillers. Both operational efficiency gains and carbon reduction must be included when considering how to most effectively contribute to the achievement of net-zero emissions across Federal operations by 2050, including a 65% reduction by 2030.

- Embodied carbon in tenant improvements: Identify the most common materials used in tenant improvements and consider their embodied carbon in making final material selections.

- Environmental product declarations: Require EPDs and set parameters around how and where they are appropriate.

- Consider requiring EPDs for 75% of materials used (by cost or weight), and that such materials have lower than average levels of embodied GHG emissions compared to functionally-equivalent products.

- Implement WBLCA early: Implement WBLCA on projects at the earliest possible stage to optimize impact.

- Consider requiring a WBLCA for larger projects (e.g. over $3M estimated total project cost), showing that the selected design, from among several design options, results in at least a 20% carbon reduction, compared to a baseline building.

- Embodied carbon benchmarking: Set embodied carbon benchmarking targets based on existing projects and ongoing data collection.

- Refrigerant selection and leakage: Consider the embodied carbon impacts of refrigerant selection and leakage. According to the Intergovernmental Panel on Climate Change, the fluorinated gases used to make refrigerants are alone responsible for 2% of all global GHG emissions.

Embodied Carbon Challenges

- Coordinating to promote consistent policy.

- Integrating WBLCA to reduce embodied carbon from a design perspective.

- Learning from and adjusting embodied carbon standards and policies as needed.

- Determining regional baselines and targets rather than national.

Partnerships & Communication

Understanding the impacts of the government’s material and product sustainability initiatives requires communicating with manufacturers, small businesses, and underserved or disadvantaged communities to understand their perspectives (e.g. Federal Buy Clean RFI![]() ). Communication allows buyers to understand the challenges, strategies, barriers, costs and trade-offs that industry must address to satisfy demand for lower embodied carbon alternatives.

). Communication allows buyers to understand the challenges, strategies, barriers, costs and trade-offs that industry must address to satisfy demand for lower embodied carbon alternatives.

Buy Clean

The Federal Government’s Buy Clean Task Force![]() is charged with developing recommendations on policies and procedures to expand consideration of embodied carbon and pollutants of several high emitting construction materials in Federal procurement and federally funded projects, which includes:

is charged with developing recommendations on policies and procedures to expand consideration of embodied carbon and pollutants of several high emitting construction materials in Federal procurement and federally funded projects, which includes:

- Identifying materials, such as concrete, steel, glass and asphalt, as well as pollutants to prioritize the use of American-made, low carbon construction materials for consideration in Federal procurement and federally-funded projects;

- Increasing the transparency of embodied carbon through supplier reporting, including incentives and technical assistance to help domestic manufacturers better report and reduce embodied carbon; and,

- Launching pilot programs to boost federal procurement of clean construction materials.

It is important to note that the Buy Clean Task Force is focused on the highest emitting materials and does not actively encourage the specification of materials already low in embodied carbon, like many biobased materials.

Embodied Carbon Case Studies

Building 48 , Lakewood, CO

, Lakewood, CO

GSA’s Building 48 at the Denver Federal Center in Lakewood, CO is an adaptive reuse project at a 150,000 GSF WWII-era munitions plant. It is reducing whole-building embodied carbon by over 85% compared to a new construction building. The project team is reusing 90% of the envelope and structure, with many new windows and skylights being added to create an attractive and effective office space. The project is targeting net zero site energy, and pursuing LEED Zero Energy certification.

Frank E. Moss U.S. Courthouse , Salt Lake City, UT

, Salt Lake City, UT

GSA’s Moss Courthouse is a seismic retrofit, backfill and renovation project that will transform the circa-1805 courthouse into an energy efficient, sustainable, modern, engaging and innovative office space. The project will structurally upgrade this legacy asset to ensure the safety of the building’s occupants and visiting public in a seismic event and upgrade many of the building’s aging systems and infrastructure. The project team is pursuing LEED Gold certification.

Consumer Financial Protection Bureau , Washington, DC

, Washington, DC

The Consumer Financial Protection Bureau agency's headquarters involves renovation and modernization of this historic building asset. Work included modifications to the building structure, upgrades to critical building systems and utilities, blast protection of the building exterior, renovation of an adjacent courtyard; installation of new architectural finishes and glazing systems, and the build-out of a new child care center, play area, conference center and fitness center. The project earned LEED Gold certification.

Kendeda Building for Innovative Sustainable Design , Atlanta, GA

, Atlanta, GA

The Kendeda Building for Innovative Sustainable Design used mass timber as the primary structural element. The design made minimal use of steel and concrete, which have much higher embodied carbon. The use of salvaged materials avoided new GHG emissions. GHG emissions were further reduced through the specification of high-recycled content products such as mineral wool insulation and brick used as rainscreen. The life cycle carbon of the project was quantified using the software Tally, so as to include manufacturing, transportation, construction and end-of-life stages.

Mahlum Portland Office , Portland, OR

, Portland, OR

The Mahlum Portland Office renovation project left the wood roof deck exposed as the finished ceiling, maintained as much of the existing concrete slab as possible, and used wood as the primary low carbon building material from structure to finish. The project team established an overall embodied carbon budget using the web-based Build Carbon Neutral tool for estimation, performed a detailed carbon footprint analysis using the software Tally, and required EPDs for product procurement.

Tools

Design Integrated Tools

- Athena Impact Estimator for Buildings (calculatelca.com) | Life Cycle Assessment Software

- a software tool that is designed to evaluate whole buildings and assemblies based on internationally recognized life cycle assessment (LCA) methodology.

- a software tool that is designed to evaluate whole buildings and assemblies based on internationally recognized life cycle assessment (LCA) methodology. - One Click LCA (oneclicklca.com)

- a web-based calculator for exploring the impacts of 10 common carbon-intensive building materials.

- a web-based calculator for exploring the impacts of 10 common carbon-intensive building materials. - Tally (choosetally.com)

- an LCA database application that enables calculating the environmental impacts of building material selections directly in an Autodesk Revit model. Tally is easy to use and requires no special modeling expertise, but it is not a free tool. Tally offers a free 10-day trial, after which users must purchase a one-year license.

- an LCA database application that enables calculating the environmental impacts of building material selections directly in an Autodesk Revit model. Tally is easy to use and requires no special modeling expertise, but it is not a free tool. Tally offers a free 10-day trial, after which users must purchase a one-year license.

Product Selection/Procurement

- EC3 (buildingtransparency.org)

- a database of building material EPDs, used for product selection and procurement. The tool allows users to access published EPDs, compare products and materials, and calculate realized or potential reductions based on material quantities.

- a database of building material EPDs, used for product selection and procurement. The tool allows users to access published EPDs, compare products and materials, and calculate realized or potential reductions based on material quantities.

Calculators

- Construction Carbon Calculator (buildcarbonneutral.org) - A CO2 calculator for your whole building project

- a web-based carbon calculator for high-level estimates of whole-building carbon impacts.

- a web-based carbon calculator for high-level estimates of whole-building carbon impacts. - EPIC Assessment (ehdd.com)

- a web-based calculator for early design-stage analysis of life cycle carbon.

- a web-based calculator for early design-stage analysis of life cycle carbon. - Kaleidoscope: Embodied Carbon Design Tool (payette.com)

- a web-based calculator used for comparing embodied carbon impacts of building assemblies.

- a web-based calculator used for comparing embodied carbon impacts of building assemblies. - Pathfinder — Improve Our Carbon Impact (climatepositivedesign.com)

- a web-based calculator for quantifying GHG emissions and sequestration potential of landscape and site design projects.

- a web-based calculator for quantifying GHG emissions and sequestration potential of landscape and site design projects. - UpStream-LCA/Upstream-Forestry-Carbon-LCA

- an excel-based tool for evaluating wood products. The tool explores GHG emissions and biogenic carbon accounting across all life cycle stages.

- an excel-based tool for evaluating wood products. The tool explores GHG emissions and biogenic carbon accounting across all life cycle stages. - CARE Tool - Carbon Avoided: Retrofit Estimator (caretool.org)

- allows users to compare the total carbon impacts of renovating an existing building vs. replacing it with a new one.

- allows users to compare the total carbon impacts of renovating an existing building vs. replacing it with a new one.

See also the Carbon Leadership Forum’s Tools for Measuring Embodied Carbon![]() page.

page.

Resources

- GSA announces

pilot Buy Clean Inflation Reduction Act Requirements for Low Embodied Carbon Construction Materials

pilot Buy Clean Inflation Reduction Act Requirements for Low Embodied Carbon Construction Materials

- Building Transparency | How to get an EPD

- GSA.gov | Embodied carbon: next steps for GSA (GSA Blog)

- Sustainability.gov | Federal Buy Clean Initiative

- EPA.gov | Sustainable Marketplace: Greener Products and Services

- DOT.gov | Low Embodied Carbon Materials

- Carbon Leadership Forum | The Carbon Challenge

- Carbon Leadership Forum | Life Cycle Assessment of Buildings (LCA): A Practice Guide

- Architecture 2030 | Embodied Carbon Actions

- Building Green | Feds Introduce Decarbonization Specs for Government Projects

- AIA | 10 steps to reducing embodied carbon

- NBI | An insider’s guide to talking about carbon neutral buildings

1. GSA.gov | GSA Green Building Advisory Committee Advice Letter Approved February 2021: Policy Recommendations for Procurement of Low Embodied Energy and Carbon Materials by Federal Agencies

Related Topics

Advanced Building Materials

Biobased Content

A product or material derived from plants or other renewable agricultural, marine, and forestry materials. Biobased products generally provide an alternative to conventional petroleum derived products and include a diverse range of offerings such as lubricants, detergents, inks, fertilizers, and bioplastics. Biobased materials can also capture carbon as part of their life cycle. Using them in buildings will store the carbon in place, preventing it from returning to the atmosphere for the life of the building. This potential is maximized by the use of rapidly renewable resources or agricultural waste streams. See the U.S. Department of Agriculture (USDA) BioPreferred![]() program for more information.

program for more information.

Read up on bioenergy basics![]() from the Department of Energy's Office of Energy Efficiency and Renewable Energy. Click the link below for more information on bio-based products and their selection.

from the Department of Energy's Office of Energy Efficiency and Renewable Energy. Click the link below for more information on bio-based products and their selection.

WBDG.org | Sustainable Design Objectives![]()

CarbonNeutralCities.org | Embodied Carbon and Bio-based Materials Factsheets![]()

Carbon Injection

CO2 from industrial processes can be added to products like concrete mixes. The injected CO2 is transformed into a mineral, locked in place, and never released back to the atmosphere.

NRDC.org | With Carbon Capture, Concrete Could One Day Be a Carbon Sink![]()

Carbon Storage

Carbon storage refers to the process of capturing and storing atmospheric CO2. It is one method of reducing the amount of CO2 in the atmosphere with the goal of slowing global climate change. Since buildings generate about 40% of all GHG emissions globally, carbon storage presents an opportunity to transform buildings into a globally significant carbon sink.