Life Cycle Assessment

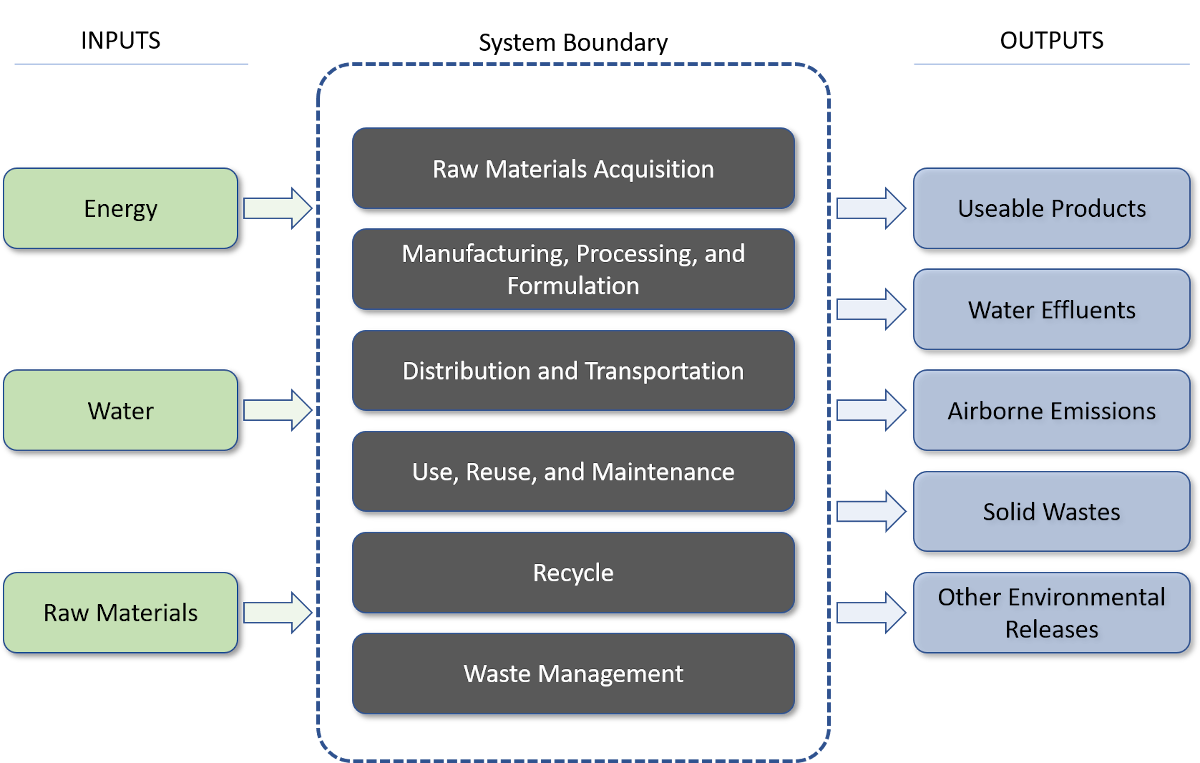

Life Cycle Assessment (LCA) aims to quantify the environmental impacts that arise from material inputs and outputs, such as energy use or air emissions, over a product’s entire life cycle to assist consumers in making decisions that will benefit the environment. LCA is typically a "cradle-to-grave" approach, which begins with the gathering of raw materials from the earth to create the product and ends at the point when all materials are returned to the earth.

The goal of LCA is to:

- Quantify or otherwise characterize all the inputs and outputs over a product’s life cycle

- Specify the potential environmental impacts of these material flows

- Consider alternative approaches that change those impacts for the better

Figure 1: Inputs and outputs over a product’s life cycle

It is important to take into consideration the entire life cycle of materials, systems, and the whole building when making design or purchasing decisions.

Benefits of LCA |

|

|---|---|

| Provide comprehensive view of the environmental impacts | See more than just the “use” phase |

| Quantify environmental effects such as overall energy consumption or air emissions | Recognize inefficiencies or significant changes across life cycle phases |

| Allow comparison of alternatives "apples to apples" | Reduce overall environmental impact and costs (as in an economic input-output LCA |

Challenges with LCA |

|

|---|---|

| Defining LCA boundaries and scope | Where do I want to draw the line? What attributes am I interested in comparing against one another? How far down the chain do I want to identify and quantify these material flows, and is that data even available? |

| Data availability | Is data available to quantify material inputs and outputs at all stages of my defined scope? Is this data from a reliable source (e.g., manufacturer)? |

| Quantifying environmental impacts | How can these material flows be quantified into environmental categories (e.g., global warming)? |

| Weighting impacts across stakeholders | What environmental category are we most concerned about (e.g., global warming, energy use, acidification) and how does it compare to other environmental attributes? |

Related Topics

Assessments

Assessments are essential tools for linking science and decision making. They survey, integrate, and synthesize science, within and between scientific disciplines and across sectors and regions.

Source: USGCRP: Assess the U.S. Climate - What are assessments?Carbon Footprint

A Carbon Footprint is the amount of greenhouse gas emissions (in units equivalent to carbon dioxide emissions) emitted by an entity, be it a person, building, company, or country.

Construction

Embodied Energy

A measure of the energy used to harvest, manufacture, process, bring to market, and dispose of a product. In Life Cycle Analysis (LCA) of building materials, embodied energy helps identify the true energy cost of an item. This accounting method attempts to quantify the fossil fuels, nuclear energy, and other forms of energy that are involved over the material's life.

Green Building

High-performance buildings exhibit environmentally responsible intent and perform in a resource efficient manner. They meet the needs of the occupants that live and work in them in a way that minimizes demand for natural resources and reduces or eliminates waste. High-performance buildings save energy, water, materials, protect the indoor environment and are designed to evolve as occupant needs change. Such buildings are generally more comfortable, healthy, durable and adaptable over time.

Greenhouse Gases (GHG)

A range of human activities cause the release of greenhouse gases into the atmosphere (e.g., the release of carbon dioxide during fuel combustion). These gasses can damage or be trapped in the earth’s atmospheric layers, contributing to global climate change.

EPA | Greenhouse Gas (GHG) Emissions![]()

Life Cycle Assessment

Life Cycle Cost Assessment (LCCA)

Materials and resources all have environmental, social and economic impacts beyond their use in a project. Impacts occur during harvest or extraction of raw materials, manufacturing, packaging, transporting, installing, use, and end-of-life disposal, reuse, or recycling. These “cradle to cradle” impacts should be considered when purchasing materials. The formal study of this process is known as Environmental Life Cycle Assessment (LCA).

Similarly, Life Cycle Cost Assessment examines the costs and savings throughout the life cycle of a building material. For example, energy efficient equipment and appliances can be more expensive when initially purchased but will save energy (and money) throughout the life of the project. Therefore, it may make sense to invest in more efficient equipment that costs more up front but saves money and energy over time.

The Sustainable Facilities Tool allows you to compare life cycle costs for materials, as well as other environmental criteria, by following the green dots and clicking "compare materials" in Explore Sustainable Workspaces.

Also, check out information on LCA at the Whole Building Design Guide:

WBDG | Life Cycle Cost Analysis (LCCA)![]()

Recycling

Recycling is the process of collecting and processing materials (that would otherwise be thrown away as trash) and remanufacturing them into new products. Recycling support stations and the education of occupants and janitorial staff are the backbone of a successful waste diversion plan. Start by confirming with the recycling hauler and compost service what materials are acceptable and the proper collection method. Separate, color-coded, well-labeled and strategically placed recycling containers and waste receptacles make sorting and collection convenient and support occupant participation.

Reuse (Waste)

Similar to recycling, reuse refers to finding new uses for items instead of sending them to landfills. Can furniture be reused in another department of the company? Can electronics be donated to charity? Even using an empty soda bottle to make a hummingbird feeder is a way to reuse items instead of trashing them.

http://consumersunion.org/pdf/ZeroReport.pdf![]()

Solid Waste

Waste comprises all materials that flow from a building to final disposal. Examples include paper, grass trimmings, food scraps, and plastics. Responsible stewardship tries to divert as much waste as possible from the landfill. This can mean recycling paper, mulching or composting grass trimmings, and reusing large items, such as furniture.

EPA | Land, Waste, and Cleanup Topics![]()

Source Reduction

Source reduction reduces the volume or toxicity of waste generated. Source reduction occurs before materials have been identified as “waste”. For example, building management can designate reuse centers for office supplies and other reusable goods. Another example of source reduction is implementing a paper reduction campaign through double sided and electronic printing.

Sustainability

Sustainability and sustainable mean to create and maintain conditions, under which humans and nature can exist inproductive harmony, that permit fulfilling the social, economic,and other requirements of present and future generations.

Sustainable Purchasing

Purchasing managers should create purchasing plans and programs that give preference to items containing recycled content, certified wood, and rapidly renewable materials, as well as items that are energy efficient, non-toxic, durable and locally manufactured, harvested and / or extracted. Further, purchasing managers should prioritize vendors who promote source reduction through reusable or minimal packaging of products.

Department of Energy | Federal Laws and Requirements Search![]()

Virgin Materials

Virgin materials are natural resources that are extracted in their raw form that are traditionally used in industrial or manufacturing processes. Examples of virgin materials are timber, plastic resin derived from petroleum refining process, and mined/processed metals.