Life Cycle Perspective (Life Cycle Thinking)

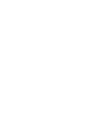

Materials and resources all have environmental, social, and economic impacts beyond just their "use" phase in a project. For a material, impacts occur during harvest or extraction of raw materials, manufacturing, packaging, transporting, installing, using and ultimately discarding (or hopefully reusing or recycling). Similarly, financial costs arise not only during the initial purchase, but also with installation, operation and maintenance, training, removal and disposal. Considering these environmental impacts and financial costs over the entire life span of the product or material is what is known as a life cycle perspective, or life cycle thinking.

A life cycle perspective provides the relevant information needed to make good decisions – to protect the environment, improve the lives of people who produce the goods, and safeguard the health of people who use them.

Two common ways to apply a life cycle perspective to buildings include Life Cycle Assessment (LCA) and Life Cycle Costing (LCC). SFTool focuses on the environmental impact of products and buildings, so after comparing and contrasting the two concepts below, the remainder of this section will address LCA.

Comparing Life Cycle Assessment and Life Cycle Costing

Life Cycle Assessment (LCA)

LCA is a systematic study examining the environmental impacts of a product from raw material extraction through production, use, and final disposal. Assessments can be “cradle-to-grave”, “cradle-to-gate” (before distribution), or “cradle-to-cradle” (cyclical or regenerative process).

For more on LCA, see the Life Cycle Assessment page.

Life Cycle Costing (LCC)

LCC is an economic analysis that considers both initial investment costs and future costs over a specific time period. The goal is to compare the overall costs of project alternatives and to select the design that ensures the facility will have the lowest total cost of ownership.

Comparison

Many people confuse life cycle assessment with life cycle costing, so the following offers a simple comparison to clarify the distinction:

| Life Cycle Assessment | Life Cycle Costing | |

|---|---|---|

| Main Focus | ENVIRONMENT & HUMAN HEALTH Find options that reduce environmental and human health impacts |

COST Find options with lowest total ownership cost |

| Scope | Typically, all life cycle stages |

Typicaly, Construction to End of Life |

| Elements | Impacts on human health, ecosystem quality, and resource use |

Costs |

| Metrics |

Each area of protection has its own metric

|

Money only

|

|

Standards/ |

ISO 14040 |

NIST Handbook 135* |